In this article we see how LTA is exploring alternative materials for more sustainable roads.

Paving the Way for Eco-friendly Roads

Everything is made of plastic these days… soon, even our roads (partly). “Hold your horses!” we hear you roar: Plastic roads? Are we planting plastic into our environment? Is plastic robust enough for heavy traffic? Will micro-particles of plastic leach into our air and water?

Fear not. LTA’s Traffic & Road Operations (TRO) divisions—Innovation & Analytics (I&A) and Road & Road Facilities Management (RRFM) —are conducting rigorous feasibility studies for different roads in Singapore with waste plastic.Here’s what they have to share.

Plastic pavement, for real

The majority of public roads in Singapore are surfaced with flexible pavement, also called asphalt-mix pavement. Other parts where traffic loading is heaviest, such as at signal junctions and bus bays, may require what is known as rigid pavement, which is a concrete mix with a reinforcing steel mesh.

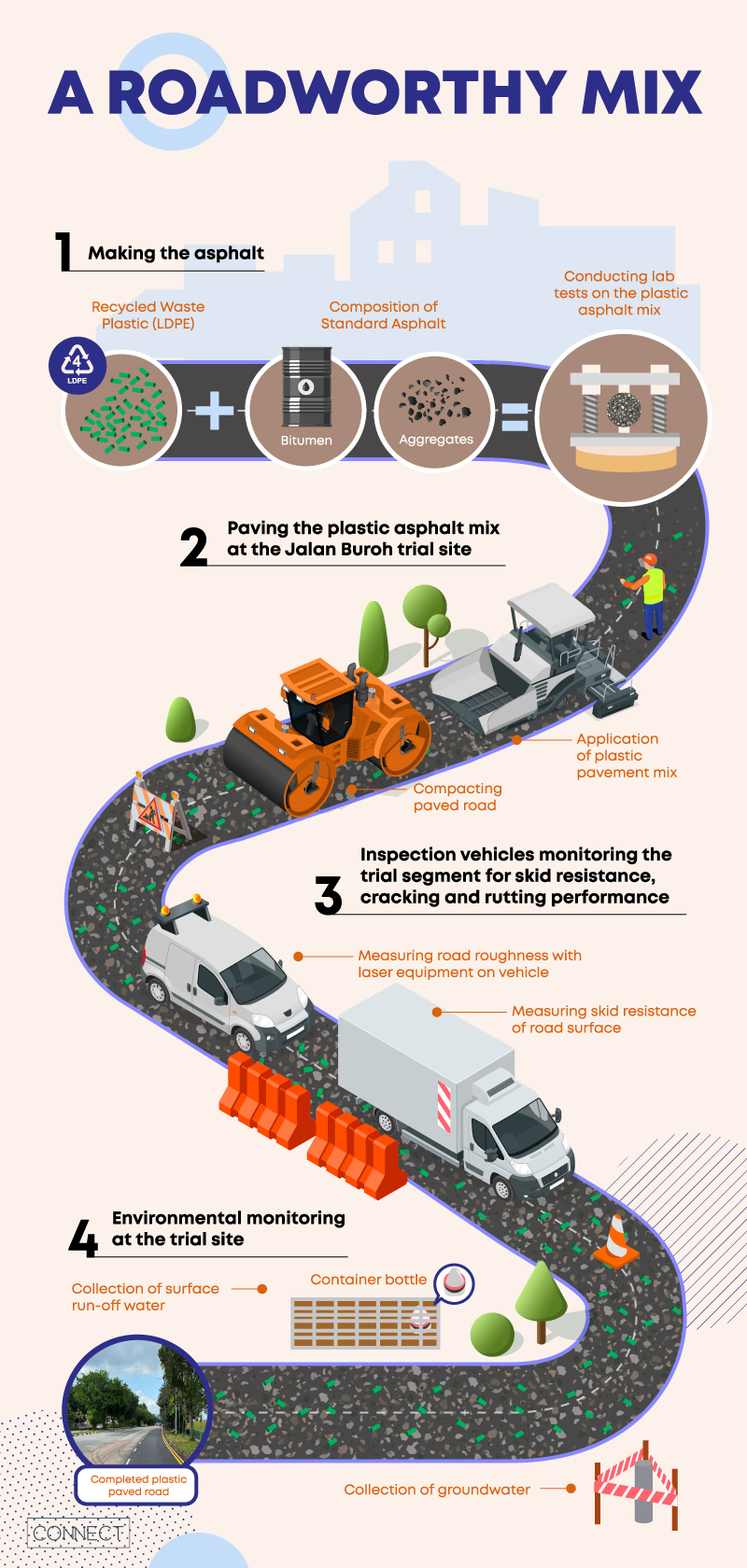

If you’ve ever wondered, a typical asphalt road is made up of 95% aggregates (with materials such as gravel, crushed stone and fine stones), and 5% bitumen or asphalt which is used to bind them together.

So would plastic or plastic wastes work in a road mix?

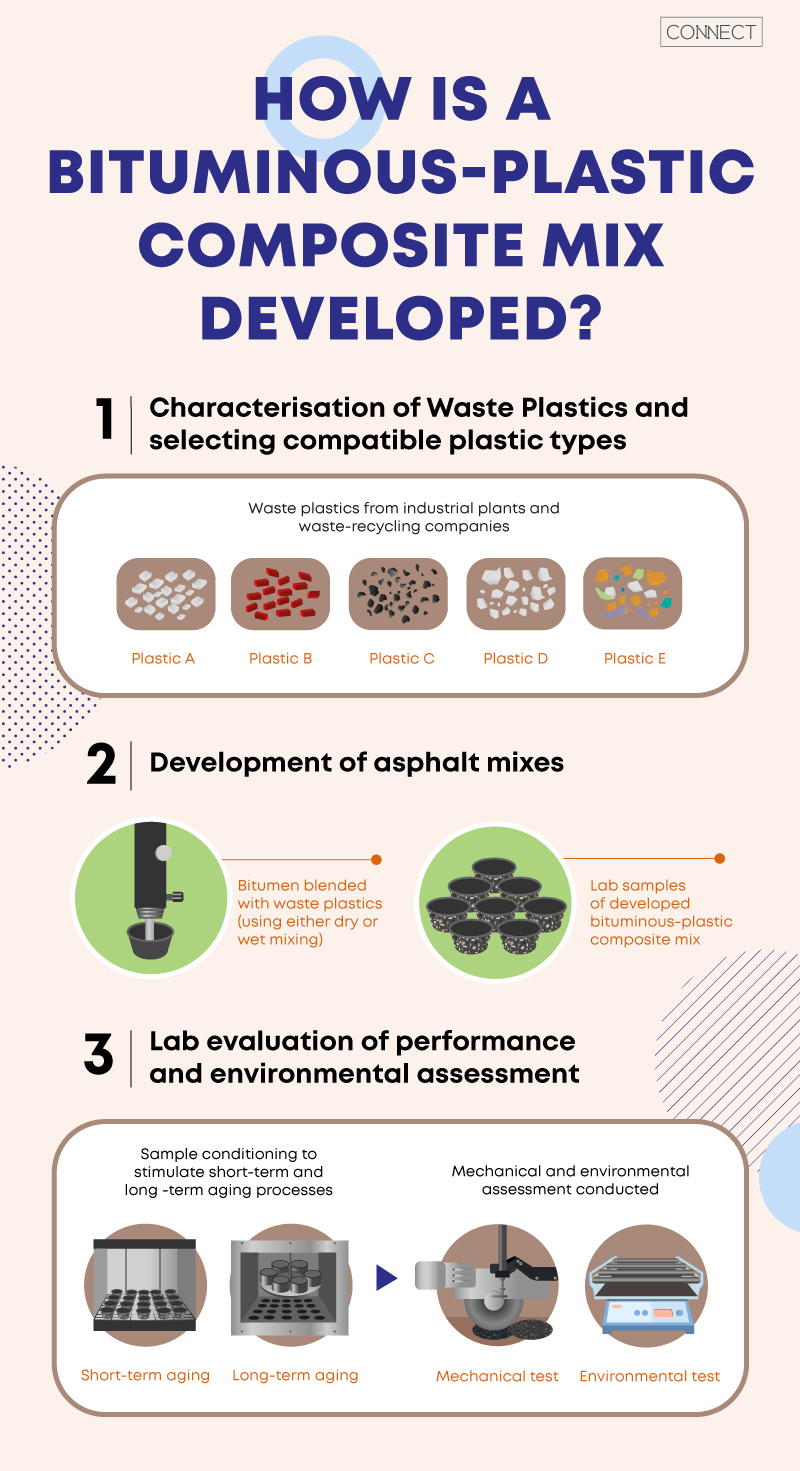

Certain plastics have indeed been used as an additive in asphalt pavement to improve performance. Which plastic types are the most compatible and readily available for such use? To find out, various processed waste plastics were assessed and added to asphalt mixes in trials by LTA and their project collaborators.

Oh, and we’re not the first to do so. Australia, India, Indonesia, Thailand and the UK have experimented with plastic roads, too. But while these were in rural areas with low traffic volumes, our tests are carried out on stretches of Singapore’s urban city roads.

Experimental plastic pavement mixes are subjected to actual traffic and local weather conditions, with their performance assessed according to relevant established methods and standards.

Tests tell it’s tough enough

LTA has taken a two-pronged approach to studying the feasibility of using waste plastics in flexible pavement. The strategy targets specific road types. The first study involved Singapore Polytechnic and Samwoh Innovation Centre* conducting laboratory studies on recycled waste plastic as additives in asphalt mix, while LTA and NEA* stepped in for the field evaluation phase.

We discovered over 12 months of monitoring that no significant defects (like potholes or cracks) formed within the trial stretch, all while meeting various performance tests.

In fact, the tests established that recycled waste plastic additives actually enhanced road durability by 30%, offering potential for its application on industrial roads plied by heavy-goods vehicles. We’re glad to report too, that based on the trial results so far, the mix brings no adverse impact to the environment!

A second, ongoing study with the National University of Singapore# is developing and evaluating the use of plastic-bituminous composite asphalt mixes. This new recipe incorporates local waste plastics with the objective of reusing and recycling them – which will support national sustainability goals by reducing the amount of waste plastic that would otherwise end up in the landfill.

So where are we at now?

Having passed lab evaluations, the developed mixes are currently being field-tested more comprehensively along stretches of the West Coast Highway and Pan Island Expressway. Although long-term field data is not yet available, lab results so far are promising!

Plastic can be good for the environment!

Since we are talking about recycling the stuff... Did you know? In these asphalt studies, one of the criteria for these mixes is that road pavements will continue to be 100% recyclable, even with the inclusion of waste plastics.

Wait—you mean our roads are being recycled?

Yes! All existing asphalt mixes are fully recyclable and can be reused in public roads, as long as they meet quality and performance standards.

Even better, we’re exploring the use of this new plastic-bituminous asphalt formula for potential extended performance, such as tyre-pavement noise reduction and urban cooling, for a more comfortable environment.

The road ahead

Having shown it can improve the lifespan of the pavement in heavy-use segments, the plastic waste additive-asphalt mix may soon become standard.

Plans are underway for large-scale staged adoption, with specifications for quality assurance and control being prepared. Eventually, we will see more of these mixes used in some industrial estates island wide. As for the new plastic-bituminous composite formula, it may be applied gradually on all other roads upon the successful completion of the trial.

A new way forward for rigid (concrete) pavement

Well and good for flexible pavement, now how about rigid pavement, you ask?

Completed trials of synthetic fibre reinforced concrete (SFRC)^ at two busy bus bays have also come up trumps with improved productivity and durability. In replacing conventional reinforcing steel mesh with synthetic fibres, SFRC can also potentially reduce construction time and costs, with a lower carbon footprint to boot, favouring it for further future use.

It may be coming to a road near you soon, having been provisioned as a viable alternative in LTA specifications, ready to be progressively adopted!

*This project is co-funded by LTA, NEA, Samwoh Innovation Centre and Singapore Polytechnic.

#This research / project is supported by the National Research Foundation, Singapore, and Land Transport Authority under Urban Mobility Grand Challenge (UMGC-L009), and Alliance to End Plastic Waste for funding studies on the recyclability of the mix at its end-of-life.

^This project is in collaboration with LTA, Samwoh Innovation Centre and Contec Fiber AG.

So here’s to taking the green route in road maintenance!

Keep a look out the next time you’re near a road and follow us as we continue to turn our road pavements into eco-friendly ones, made of alternative materials.

From East to West, CRL Trivia to Pique Your Interest!

From East to West, CRL Trivia to Pique Your Interest!

10 Reasons the TEL is an Engine-nious Development

10 Reasons the TEL is an Engine-nious Development

Singapore's Road EMAS-gency Experts

Singapore's Road EMAS-gency Experts

Take a brake! Explore these eight hidden gems on your bike

Take a brake! Explore these eight hidden gems on your bike

Stations, stations on the tracks, which is the greenest of them all?

Stations, stations on the tracks, which is the greenest of them all?

To Turn or Not to Turn?

To Turn or Not to Turn?

TEL3 Hits the City: Get Fed, Get Fit and Feel Fab!

TEL3 Hits the City: Get Fed, Get Fit and Feel Fab!

Making a "PID-Stop" at one of our bus stops?

Making a "PID-Stop" at one of our bus stops?

Easy, Breezy, Families Ride Easy!

Easy, Breezy, Families Ride Easy!

.jpg) Staying Sharp: Keeping Public Transport Safe

Staying Sharp: Keeping Public Transport Safe

Tactile Guiding System in Singapore

Tactile Guiding System in Singapore

What lies beneath: LTA's Digging Machine

What lies beneath: LTA's Digging Machine

Excuse me, are you a boring engineer?

Excuse me, are you a boring engineer?

9 Cycling Tips from The Woke Salaryman

9 Cycling Tips from The Woke Salaryman

Look Ma, No Hands!

Look Ma, No Hands!

Introducing Singapore’s Longest Transit Priority Corridor

Introducing Singapore’s Longest Transit Priority Corridor

Nifty Wayfinding

Nifty Wayfinding

Making a Mark in 3D

Making a Mark in 3D

The Perks of Pedestrianisation

The Perks of Pedestrianisation